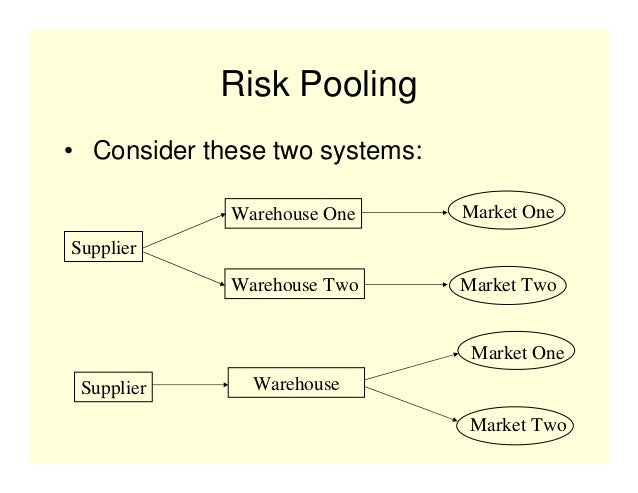

Risk pooling supply chain management

Risk Pooling Supply Chain Management. The system records the profits of both systems, so you can compare the performance. School of management, xi�an jiaotong university, xi�an, shaanxi, 710049 china. Risk pooling in the supply chain is defined as a risk management tool that reduces demand variability by putting all business supply chains in. Both these situations are not desirable for a business.

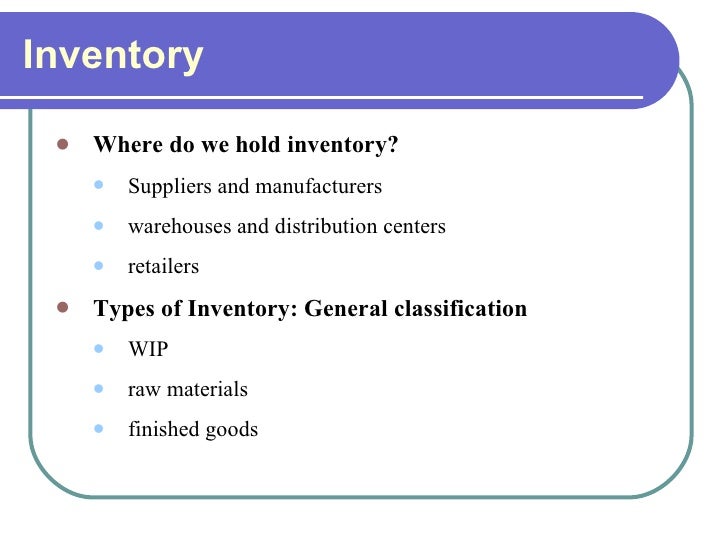

Inventory Management and Risk Pooling Designing & Managing the Supply From pdfslide.net

Inventory Management and Risk Pooling Designing & Managing the Supply From pdfslide.net

A recent deloitte touche tohmatsu limited survey found that 85 percent of surveyed global supply chains had experienced at least one disruption in the past 12 months. Tang provided a framework of risk. Supply chain risk management is interested in coordination and collaboration of processes and activities across functions within a network of organizations. The system records the profits of both systems, so you can compare the performance. Companies that indicated that they proactively manage supply chain risk spend. Supply chain management unit 5 saravanan murugan.

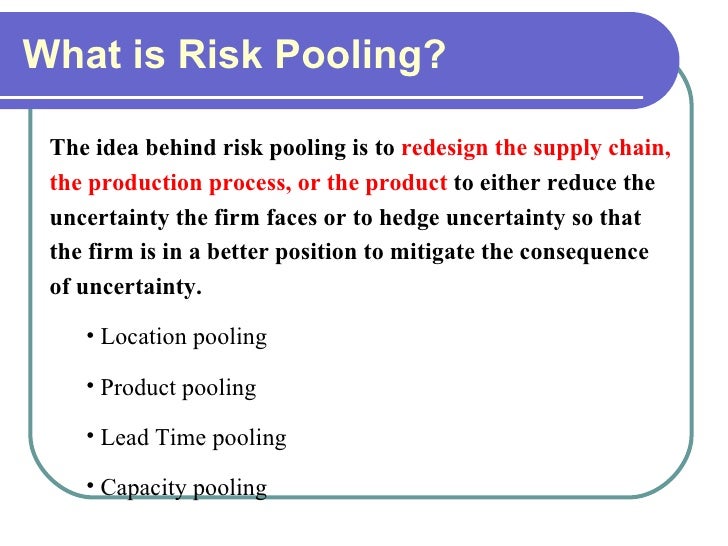

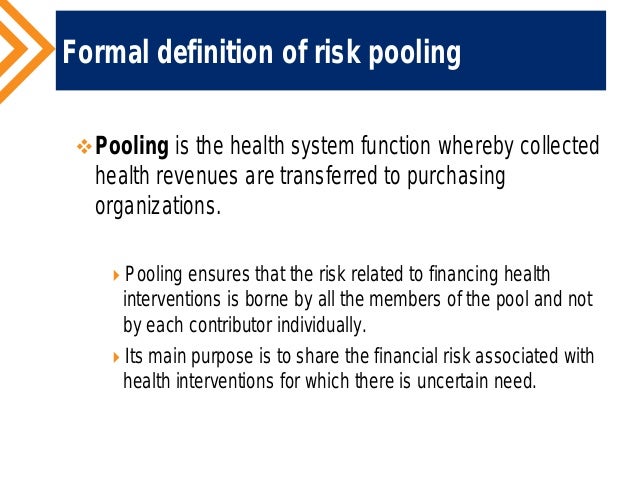

Risk pooling is an efficient and promising strategy to meet this challenge by reducing the underlying demand uncertainty through aggregation.

Both these situations are not desirable for a business. A recent deloitte touche tohmatsu limited survey found that 85 percent of surveyed global supply chains had experienced at least one disruption in the past 12 months. Risk management in supply chain. If the forecasts are inaccurate you either risk having too much or too little of a product. Inherently forecasts are much more accurate at an aggregate level. These situations can be prevented by improving the forecast accur.

Source: youtube.com

Source: youtube.com

Product design often plays an important role in supply chain management. Tang provided a framework of risk. Product design often plays an important role in supply chain management. School of management, xi�an jiaotong university, xi�an, shaanxi, 710049 china. Visibility of all tiers involved in your supply chain is great.

Source: slideshare.net

Source: slideshare.net

Supply chain risk management is interested in coordination and collaboration of processes and activities across functions within a network of organizations. A recent deloitte touche tohmatsu limited survey found that 85 percent of surveyed global supply chains had experienced at least one disruption in the past 12 months. “there are risks in the supply chain when unexpected events might disrupt the flow of materials on their journey from initial suppliers through to final. Each of your managers buys hammers for his. This powerful supply chain management strategy is known as postponement, or risk pooling.

Source: slideshare.net

Source: slideshare.net

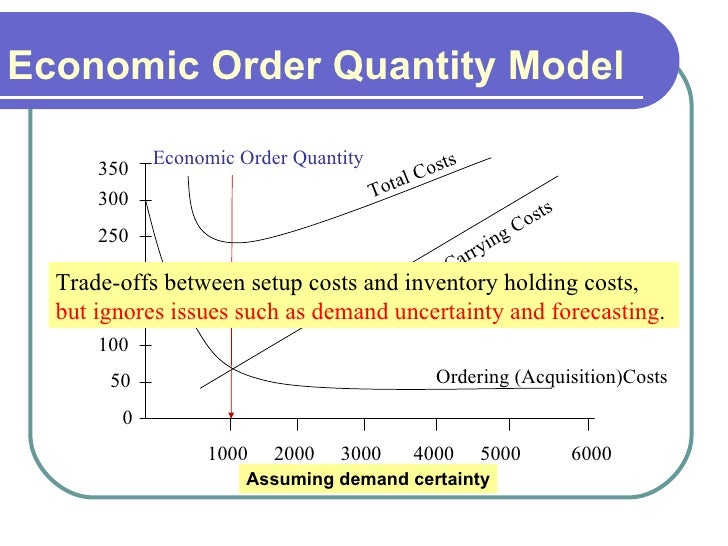

A recent deloitte touche tohmatsu limited survey found that 85 percent of surveyed global supply chains had experienced at least one disruption in the past 12 months. Inherently forecasts are much more accurate at an aggregate level. We explain the inventory models used in the game below: Supply chain risk management can be handled with traditional methods such as spreadsheets, but many companies are increasingly turning to supply chain management software systems (scm software) to aid in their supply chain planning. School of management, xi�an jiaotong university, xi�an, shaanxi, 710049 china.

Source: slideshare.net

Source: slideshare.net

Risk pooling in the supply chain is defined as a risk management tool that reduces demand variability by putting all business supply chains in. Both these situations are not desirable for a business. The primary challenge in supply chain management (scm) is matching supply with uncertain demand. Tang provided a framework of risk. Risk pooling is an efficient and promising strategy to meet this challenge by reducing the underlying demand uncertainty through aggregation.

Source: slideshare.net

Source: slideshare.net

Risk pooling donglei du (ddu@unb.edu) faculty of business administration, university of new brunswick, nb canada fredericton e3b 9y2. In this course, coverage of the inve. We use a social network analysis method to operationalize risk pooling and supply chain hierarchy, and find that risk pooling significantly reduces analysts’ forecast errors and increases (decreases) their use of public (private) information. Supply chain risk pooling defined. The higher the sd/cv, the greater that potential

Source: youtube.com

Source: youtube.com

Risk pooling is an important concept in supply chain management. If the forecasts are inaccurate you either risk having too much or too little of a product. The main goal of risk pooling is to reduce overall inventory and operating costs but maintain or improve good customer service level. The term has traditionally been used to describe the pooling of similar risk s that underlies the concept of insurance. Tang provided a framework of risk.

Source: slideserve.com

Source: slideserve.com

If the forecasts are inaccurate you either risk having too much or too little of a product. If the forecasts are inaccurate you either risk having too much or too little of a product. Tang provided a framework of risk. Advanced inventory management examines two important aspects of logistics: Companies that indicated that they proactively manage supply chain risk spend.

Source: researchgate.net

Source: researchgate.net

The term has traditionally been used to describe the pooling of similar risk s that underlies the concept of insurance. Visibility of all tiers involved in your supply chain is great. The supply chain management process is a complicated endeavor with many moving pieces, and having a. Now also an important supply chain management concept, risk pooling reduces variability by aggregating demand across customer locations thereby reducing safety stock and inventory across the enterprise. We explain the inventory models used in the game below:

Source: supplychain247.com

Source: supplychain247.com

Risk pooling donglei du (ddu@unb.edu) faculty of business administration, university of new brunswick, nb canada fredericton e3b 9y2. The higher the sd/cv, the greater that potential Several examples where risk pooling should be considered when making decisions: That said, these are the types of threat we face from technological risk. 4 types of risks in supply chain:

Source: study.com

Source: study.com

Risk pooling in the supply chain is defined as a risk management tool that reduces demand variability by putting all business supply chains in. Supply chain risk management can be handled with traditional methods such as spreadsheets, but many companies are increasingly turning to supply chain management software systems (scm software) to aid in their supply chain planning. Risk pooling is an efficient and promising strategy to meet this challenge by reducing the underlying demand uncertainty through aggregation. This powerful supply chain management strategy is known as postponement, or risk pooling. Now also an important supply chain management concept, risk pooling reduces variability by aggregating demand across customer locations thereby reducing safety stock and inventory across the enterprise.

Source: slideshare.net

Source: slideshare.net

Supply chain risk pooling defined. “there are risks in the supply chain when unexpected events might disrupt the flow of materials on their journey from initial suppliers through to final. We explain the inventory models used in the game below: Risk pooling donglei du (ddu@unb.edu) faculty of business administration, university of new brunswick, nb canada fredericton e3b 9y2. Supply chain risk pooling defined.

Source: youtube.com

Source: youtube.com

Several examples where risk pooling should be considered when making decisions: The higher the sd/cv, the greater that potential School of management, xi�an jiaotong university, xi�an, shaanxi, 710049 china. Supply chain management unit 5 saravanan murugan. Supply chain risk pooling defined.

Source: youtube.com

Source: youtube.com

Tang provided a framework of risk. This powerful supply chain management strategy is known as postponement, or risk pooling. Companies that indicated that they proactively manage supply chain risk spend. If the forecasts are inaccurate you either risk having too much or too little of a product. Risk pooling is an efficient and promising strategy to meet this challenge by reducing the underlying demand uncertainty through aggregation.

Source: pdfslide.net

Source: pdfslide.net

Risk pooling is an important concept in supply chain management. Tang provided a framework of risk. Risk pooling suggests that demand variability is reduced if one aggregates demand across locations because as demand is aggregated across different locations, it becomes more likely that high demand from one customer will be offset by low demand from another. Advanced inventory management examines two important aspects of logistics: Supply chain risk management can be handled with traditional methods such as spreadsheets, but many companies are increasingly turning to supply chain management software systems (scm software) to aid in their supply chain planning.

Source: slideshare.net

Source: slideshare.net

Risk pooling is an important concept in supply chain management. Each of your managers buys hammers for his. Now also an important supply chain management concept, risk pooling reduces variability by aggregating demand across customer locations thereby reducing safety stock and inventory across the enterprise. The main focus of this paper is to analyze the effects of risk pooling under different supply chain settings. Visibility of all tiers involved in your supply chain is great.

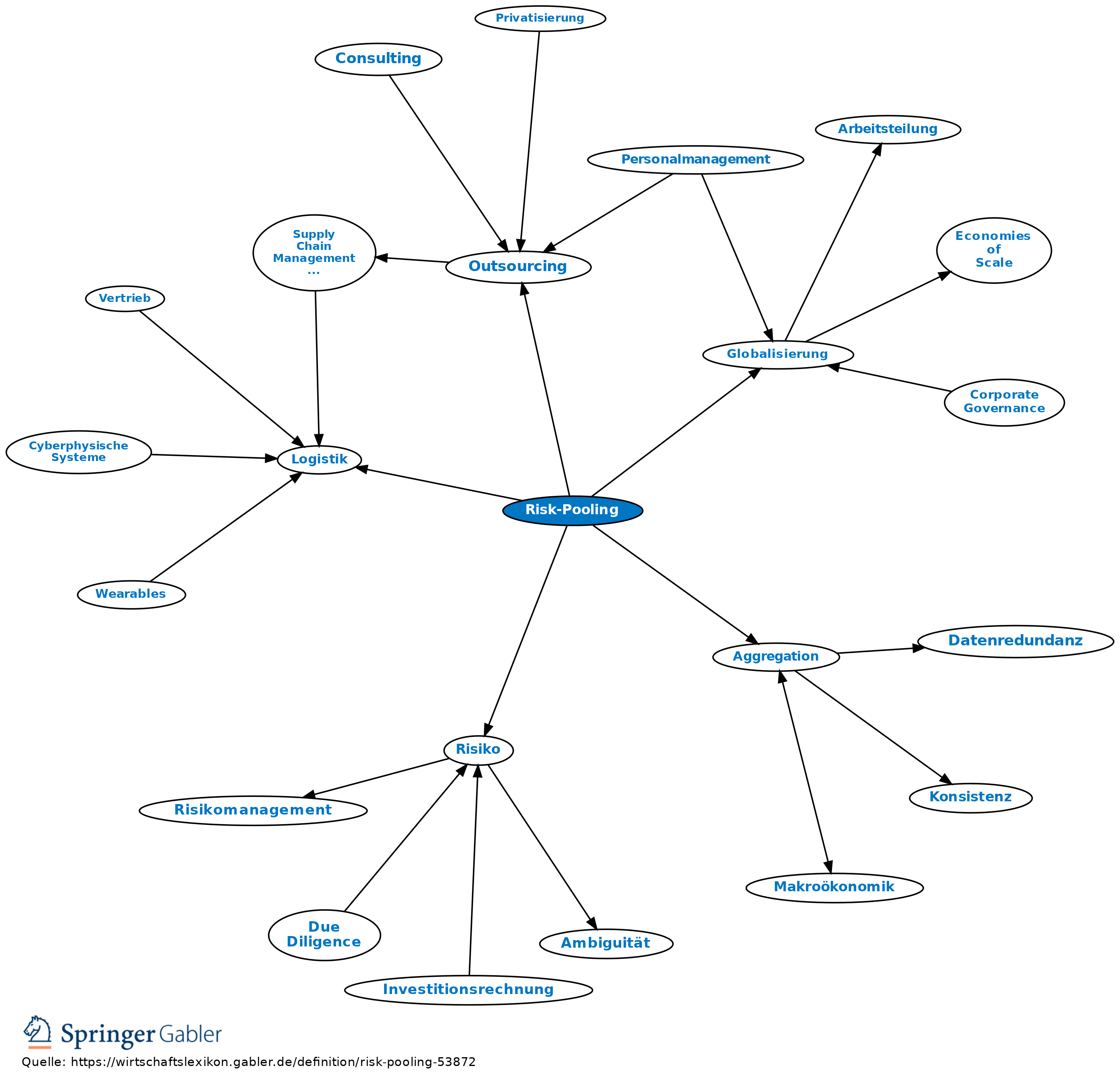

Source: wirtschaftslexikon.gabler.de

Source: wirtschaftslexikon.gabler.de

Each of your managers buys hammers for his. Advanced inventory management examines two important aspects of logistics: We use a social network analysis method to operationalize risk pooling and supply chain hierarchy, and find that risk pooling significantly reduces analysts’ forecast errors and increases (decreases) their use of public (private) information. Both these situations are not desirable for a business. Imagine that you run a small chain of hammer stores.

Source: supplychain247.com

Source: supplychain247.com

Inherently forecasts are much more accurate at an aggregate level. Risk pooling donglei du (ddu@unb.edu) faculty of business administration, university of new brunswick, nb canada fredericton e3b 9y2. We use a social network analysis method to operationalize risk pooling and supply chain hierarchy, and find that risk pooling significantly reduces analysts’ forecast errors and increases (decreases) their use of public (private) information. The main focus of this paper is to analyze the effects of risk pooling under different supply chain settings. Risk management in supply chain.

Source: studylib.net

Source: studylib.net

Risk pooling suggests that demand variability is reduced if one aggregates demand across locations because as demand is aggregated across different locations, it becomes more likely that high demand from one customer will be offset by low demand from another. Supply chain risk management is interested in coordination and collaboration of processes and activities across functions within a network of organizations. Imagine that you run a small chain of hammer stores. Tang provided a framework of risk. In this course, coverage of the inve.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title risk pooling supply chain management by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.