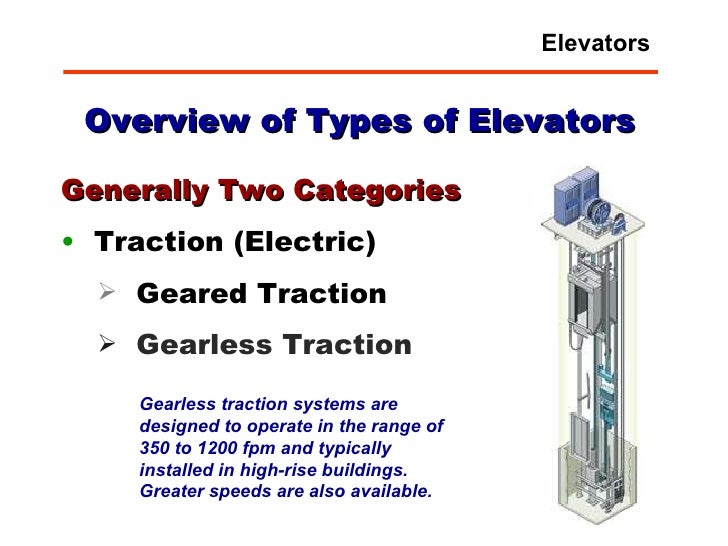

Geared vs gearless traction elevator

Geared Vs Gearless Traction Elevator. Geared traction elevators have a gearbox that is attached to the motor, which drives the wheel that moves the ropes. Geared traction elevators are capable of travel speeds up to 500 feet per minute. 1.normally pm motor used for gearless lift and induction motor used for geared lift. Geared traction elevators can move at speeds of up to 152 m per minute and a maximum height of nearly 75 m, while gearless traction elevators can move at speeds of up to 610 m per minute and distances of up to 600 m.

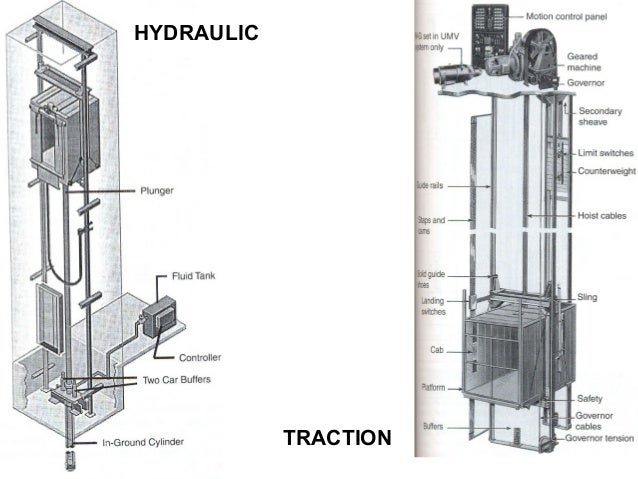

Traction Versus Hydraulic Elevators From tkelevator.com

Traction Versus Hydraulic Elevators From tkelevator.com

Geared traction elevators are driven by either direct current (dc) or alternating current (ac) and their maximum speed is up to 500 ft. Geared traction elevators have a gearbox that is attached to the motor, which drives the wheel that moves the ropes. So insist on a real overhead traction gearless machine not something engineered to fit behind a rail or something. Geared traction elevators are capable of travel speeds up to 500 feet per minute. Installation expenses of this type of elevator are less than gearless traction elevators have. The main function of the gears is to power the wheel that moves the ropes.

So insist on a real overhead traction gearless machine not something engineered to fit behind a rail or something.

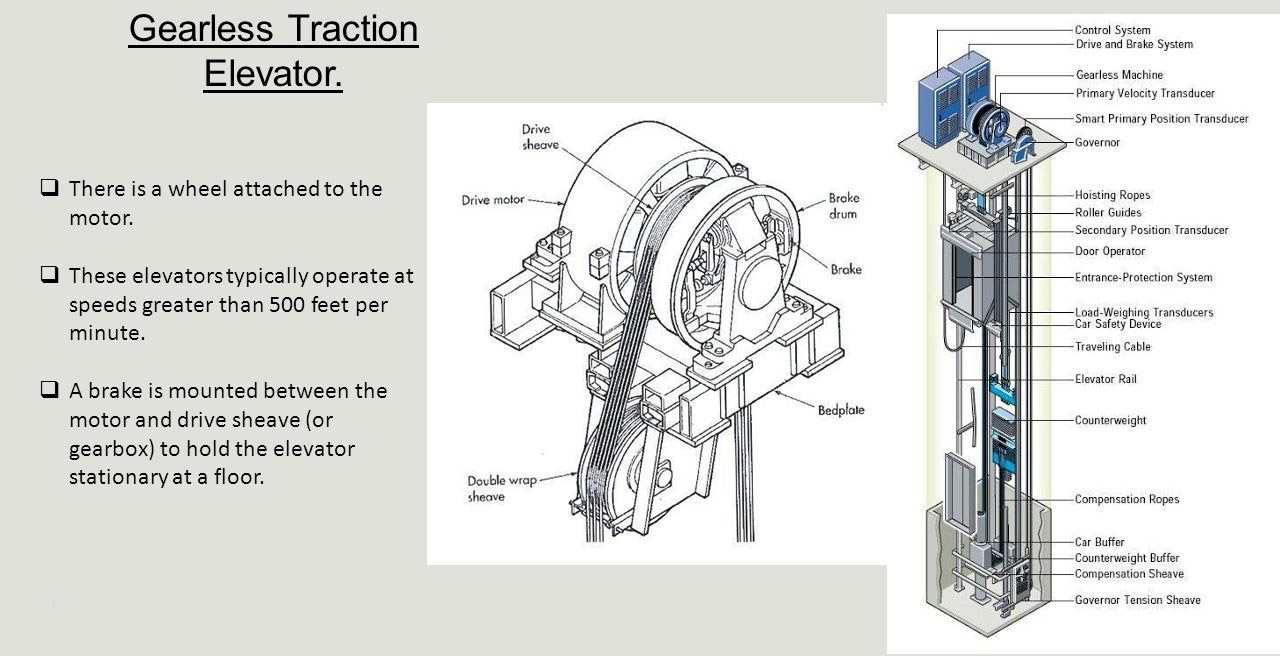

The main function of the gears is to power the wheel that moves the ropes. The system has a brake between the motor and the reduction unit, this brake stopped the. Geared traction elevators are capable of travel speeds up to 500 feet per minute. Gearless machines are highly energy efficient, especially when equipped with the latest in gearless ac or dc drive technology. The main function of the gears is to power the wheel that moves the ropes. Traction elevators are lifted by ropes, which pass over a wheel attached to an electric motor above the elevator shaft.

Source: apicsllc.com

Source: apicsllc.com

So insist on a real overhead traction gearless machine not something engineered to fit behind a rail or something. Geared traction elevators have a gearbox that is attached to the motor, which drives the wheel that moves the ropes. Gearless machines are highly energy efficient, especially when equipped with the latest in gearless ac or dc drive technology. The system has a brake between the motor and the reduction unit, this brake stopped the. Gearless is better and much more popular.

Source: alienslift.com

Source: alienslift.com

This speed limit is lower than gearless. As a result, gearless material lift machines do not need a machine room. Geared motors are preferred because of their. Geared traction elevators can travel with up to 152 m per minute speed and a maximum of nearly 75 m height, while gearless traction elevators can speed up to 610 m per minute with max 600 m travel distance. However, in a gearless traction elevator, the wheel is directly connected to the engine and the cabin.

Source: slideshare.net

Source: slideshare.net

However, in a gearless traction elevator, the wheel is directly connected to the engine and the cabin. Installation expenses of this type of elevator are less than gearless traction elevators have. In addition to reduced energy consumption, gearless traction elevators move at speeds of up to 2,000 feet per minute. The maximum loading capacity is nearly 13600 kg. While the lift rates are slower than in a typical gearless elevator, the gear reduction offers the advantage of requiring a less powerful motor to turn the sheave.

Source: authorstream.com

Source: authorstream.com

Installation expenses of this type of elevator are less than gearless traction elevators have. Gearless is better and much more popular. Geared vs gearless traction elevator; Wholesale geared vs gearless traction elevator manufacturers & suppliers from china. Geared traction elevators have a gearbox that is attached to the motor, which drives the wheel that moves the ropes.

Source: tkelevator.com

Source: tkelevator.com

These traction elevators have a gearbox which is attached to the electric motor and turns the hoist sheave and moves the rope. In the gearless traction elevators, the wheels are. Traction elevators are lifted by ropes, which pass over a wheel attached to an electric motor above the elevator shaft. While the lift rates are slower than in a typical gearless elevator, the gear reduction offers the advantage of requiring a less powerful motor to turn the sheave. The geared elevator is made up of a motor that has a gearbox attached to it.

Source: isfelevator.com

Source: isfelevator.com

Geared traction elevators are powered by direct current or alternating current and the maximum speed of. However, in a gearless traction elevator, the wheel is directly connected to the engine and the cabin. In geared elevators, the gearboxes are attached to the electric motor and turn the hoisting sheave and move the rope whereas in the case of gearless elevators the gearbox is attached directly to the motor. Traction elevators are lifted by ropes, which pass over a wheel attached to an electric motor above the elevator shaft. Although one of them has distinct advantages compared to the latter, the best choice can always change according to the needs, abilities, adequateness.

Source: xinda-elevator.com

Source: xinda-elevator.com

Gearless machines are highly energy efficient, especially when equipped with the latest in gearless ac or dc drive technology. Geared elevators offer advantages in terms of energy efficiency as they use less power to run the elevator shaft. But, both geared and gearless lifts have nearly the same load capacity which is enough for passenger travel. Geared vs gearless traction elevator is a common comparison that builders try to figure at all projects. In the gearless traction elevators, the wheels are.

Source: indiamart.com

Source: indiamart.com

Geared and gearless traction elevators with machine room. Geared elevators offer advantages in terms of energy efficiency as they use less power to run the elevator shaft. A machine room is built above the elevator shaft and is used to mount the wheel and electric motor. The maximum loading capacity is nearly 13600 kg. As a result, gearless material lift machines do not need a machine room.

Source: slideserve.com

Source: slideserve.com

However, the load capacity of both geared and gearless elevators is approximately the same and is sufficient for. Geared vs gearless traction elevator; While the lift rates are slower than in a typical gearless elevator, the gear reduction offers the advantage of requiring a less powerful motor to turn the sheave. Gearless machines are highly energy efficient, especially when equipped with the latest in gearless ac or dc drive technology. Gearless traction elevators have a very high travel speed of up to 2000 ft.

Source: pinterest.com

Source: pinterest.com

Simple as stated that lift which machine don�t have gear gear is called gearless and lift which machine have gear called geared lift. Although one of them has distinct advantages compared to the latter, the best choice can always change according to the needs, abilities, adequateness. The standing of the wheel is the main difference among both the elevators. Geared traction elevators are powered by direct current or alternating current and the maximum speed of. The maximum travel distance for a geared traction elevator is around 250 feet.

Source: slideshare.net

Source: slideshare.net

Their maximum travel distance is almost 2000 ft. Geared traction elevators can travel with up to 152 m per minute speed and a maximum of nearly 75 m height, while gearless traction elevators can speed up to 610 m per minute with max 600 m travel distance. Geared vs gearless traction elevator; Geared traction elevators can move at speeds of up to 152 m per minute and a maximum height of nearly 75 m, while gearless traction elevators can move at speeds of up to 610 m per minute and distances of up to 600 m. A machine room is built above the elevator shaft and is used to mount the wheel and electric motor.

Source: quora.com

1.normally pm motor used for gearless lift and induction motor used for geared lift. Geared traction elevators are driven by either direct current (dc) or alternating current (ac) and their maximum speed is up to 500 ft. Geared vs gearless traction elevator is a common comparison that builders try to figure at all projects. A counter weight makes the elevators more efficient by. 1.normally pm motor used for gearless lift and induction motor used for geared lift.

Source: slideshare.net

Source: slideshare.net

Although one of them has distinct advantages compared to the latter, the best choice can always change according to the needs, abilities, adequateness. However, the load capacity of both geared and gearless elevators is approximately the same and is sufficient for. The main function of the gears is to power the wheel that moves the ropes. Installation expenses of this type of elevator are less than gearless traction elevators have. A machine room is built above the elevator shaft and is used to mount the wheel and electric motor.

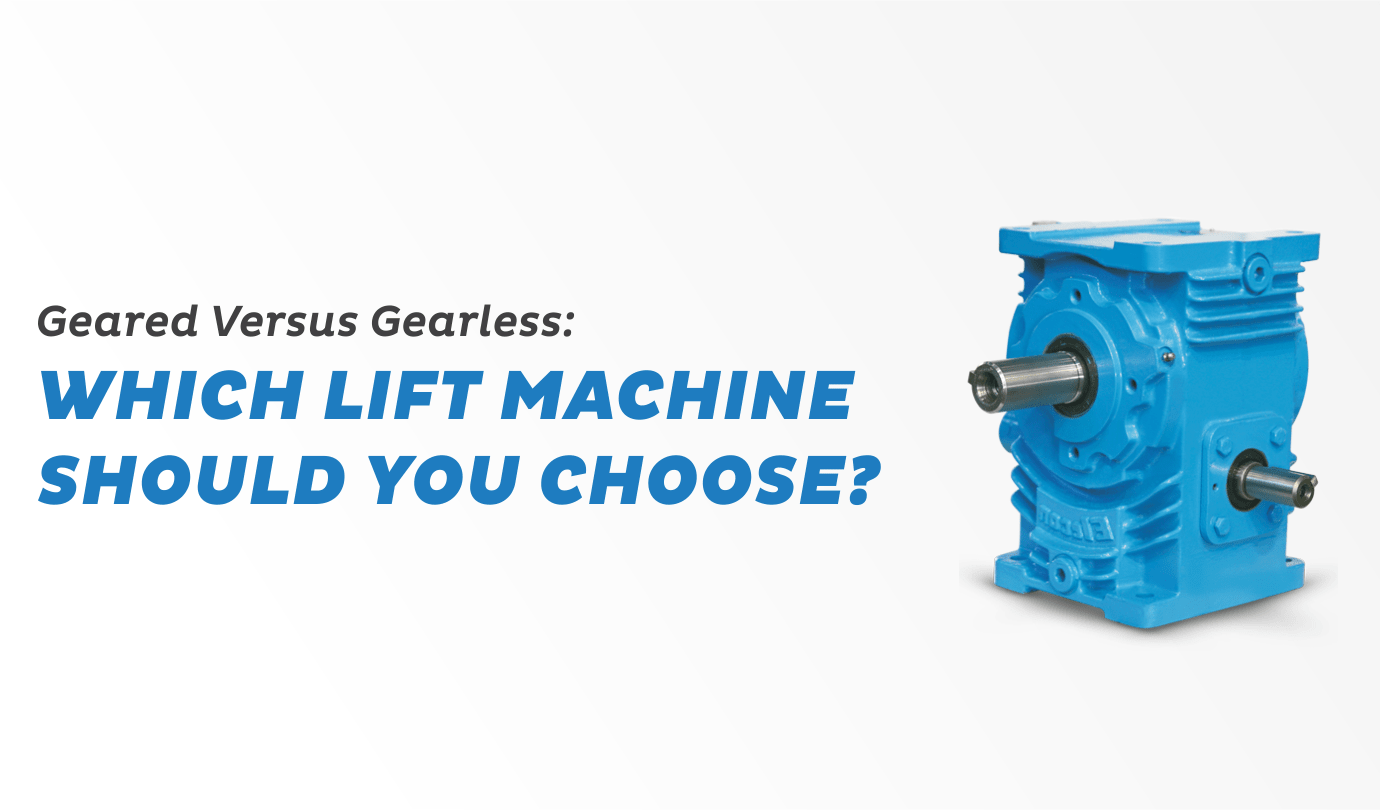

Source: premium-transmission.com

Source: premium-transmission.com

Geared traction elevators can travel with up to 152 m per minute speed and a maximum of nearly 75 m height, while gearless traction elevators can speed up to 610 m per minute with max 600 m travel distance. In the gearless traction elevators, the wheels are. Geared traction elevators are driven by either direct current (dc) or alternating current (ac) and their maximum speed is up to 500 ft. For example, a regenerative drive recycles energy back into the grid, which can further lower energy costs for a building. Elevator driven by geared motor covers less than 10% of the total production units of all elevators in 2013.

Source: isfelevator.com

Source: isfelevator.com

Gearless machines are highly energy efficient, especially when equipped with the latest in gearless ac or dc drive technology. Geared vs gearless traction elevator; In the gearless traction elevators, the wheels are. Geared vs gearless traction lift. Elevator driven by geared motor covers less than 10% of the total production units of all elevators in 2013.

Source: mitsubishielectric.com

Source: mitsubishielectric.com

Their maximum travel distance is almost 2000 ft. In the gearless traction elevators, the wheels are. The main function of the gears is to power the wheel that moves the ropes. Geared traction elevators can travel with up to 152 m per minute speed and a maximum of nearly 75 m height, while gearless traction elevators can speed up to 610 m per minute with max 600 m travel distance. For example, a regenerative drive recycles energy back into the grid, which can further lower energy costs for a building.

Source: tradeindia.com

Source: tradeindia.com

Traction elevators are lifted by ropes, which pass over a wheel attached to an electric motor above the elevator shaft. In addition to reduced energy consumption, gearless traction elevators move at speeds of up to 2,000 feet per minute. This is useful to use low kw motor and reduce cost. Geared traction elevators are powered by direct current or alternating current and the maximum speed of. The working speed employed in this design for geared traction elevators is between 1,7 to 2,5 meters per second.

Source: titannewlifts.co.uk

Source: titannewlifts.co.uk

However, the load capacity of both geared and gearless elevators is approximately the same and is sufficient for. For example, a regenerative drive recycles energy back into the grid, which can further lower energy costs for a building. So insist on a real overhead traction gearless machine not something engineered to fit behind a rail or something. However, in a gearless traction elevator, the wheel is directly connected to the engine and the cabin. Geared vs gearless traction elevator;

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title geared vs gearless traction elevator by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.