Characteristics of natural fibres

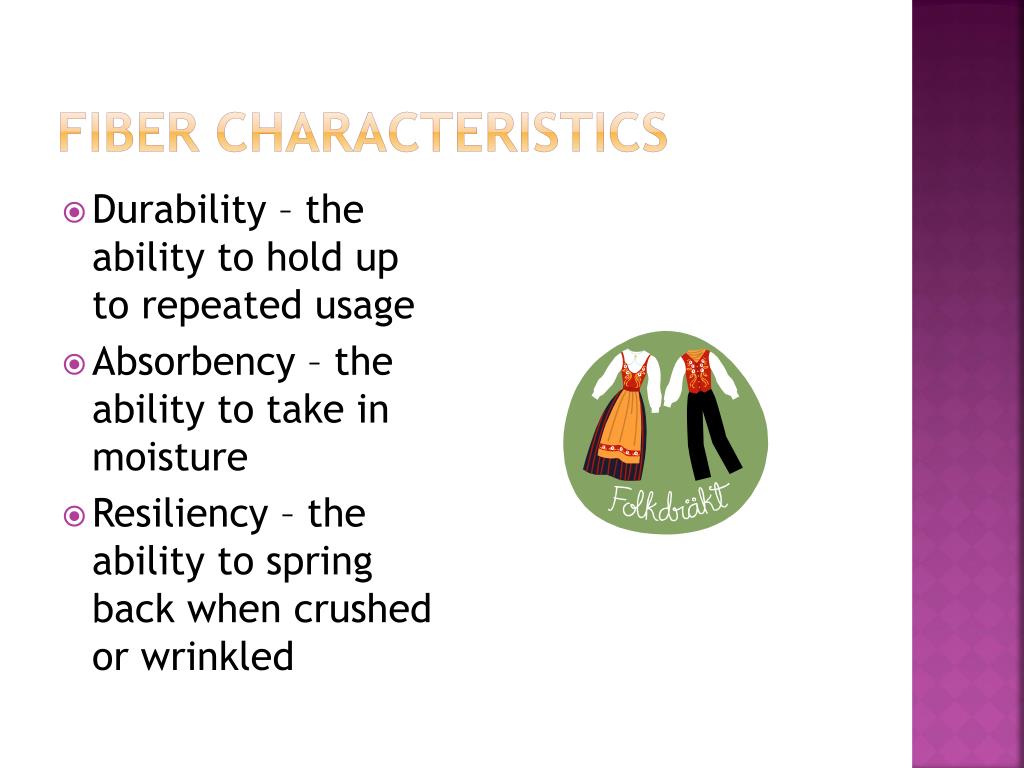

Characteristics Of Natural Fibres. You can find natural and synthetic fibers among the world�s most used fibers for textiles. Synthetic fibres is prepared from chemical substances in the industry. A natural fibre may be further defined as an agglomeration of cells in which the diameter is negligible in comparison with the length. Most natural fibres have considerable differences in mechanical properties and moisture absorption and have poor thermal characteristics, creating problems in the production of natural fibre composites.

Properties, prossesing of natural fiber From slideshare.net

Properties, prossesing of natural fiber From slideshare.net

Nylon has a lower specific gravity than other fibres. Physical properties of wool fibre: The protein core will absorb up to 30% of its weight in moisture without becoming damp or. The automotive and aerospace sectors represent the best opportunity for natural fibers due to their favorable characteristics such as lower weight, better crash absorbance and sound insulation properties. Natural fibers are produced by plants, animals, and geological processes. They are easy to maintain and wash and are resistant to attack by moths.

The inherent characteristics and properties of natural fibers, generally issues like poor adhesion, moisture absorption, poor wet ability, etc., cause lower bonding with the polymer matrix.

This article reports the extraction process of. Therefore, modification or pretreatment of natural fibers is done prior to composite preparation. They can be used as a component of composite materials, where the orientation of fibers impacts the properties. Synthetic fibres don’t get wrinkles after washing and are extremely lightweight. Synthetic fibres have high abrasion. While designing composite parts, the.

Source: researchgate.net

Source: researchgate.net

The invention of cloth was a milestone in the history of civilization. Visit byju’s to learn more about, examples, types, advantage, videos and faqs of synthetic and natural fibres. The protein core will absorb up to 30% of its weight in moisture without becoming damp or. Most natural fibres have considerable differences in mechanical properties and moisture absorption and have poor thermal characteristics, creating problems in the production of natural fibre composites. Synthetic fibres is prepared from chemical substances in the industry.

Source: style2designer.com

Source: style2designer.com

This article reports the extraction process of. Synthetic fibres don’t get wrinkles after washing and are extremely lightweight. Hemp is soft, breathable, lightweight, and durable but wrinkles easily. Cashmere obtained from cashmere goats and other goats. The automotive and aerospace sectors represent the best opportunity for natural fibers due to their favorable characteristics such as lower weight, better crash absorbance and sound insulation properties.

Source: researchgate.net

Source: researchgate.net

The automotive and aerospace sectors represent the best opportunity for natural fibers due to their favorable characteristics such as lower weight, better crash absorbance and sound insulation properties. It�s a great material to create comfortable textiles and beautiful fashion with fantastic qualities. You can find natural and synthetic fibers among the world�s most used fibers for textiles. Molaba, in encyclopedia of materials: There are 5 steps in processing cashmere:

![Properties of natural fibres with synthetic fibres [23],[41] Download Properties of natural fibres with synthetic fibres [23],[41] Download](https://www.researchgate.net/profile/Saravanan_Boobalan/publication/295980159/figure/download/tbl2/AS:669454962806800@1536621909404/Properties-of-natural-fibres-with-synthetic-fibres-23-41.png) Source: researchgate.net

Source: researchgate.net

The natural fibers have been abundantly available in the world. They are easy to maintain and wash and are resistant to attack by moths. Natural fibers can also be matted into sheets to make paper or felt. Absorbent fibers have less static cling. Therefore, modification or pretreatment of natural fibers is done prior to composite preparation.

Source: slideserve.com

Source: slideserve.com

Visit byju’s to learn more about, examples, types, advantage, videos and faqs of synthetic and natural fibres. Visit byju’s to learn more about, examples, types, advantage, videos and faqs of synthetic and natural fibres. Natural fibre, any hairlike raw material directly obtainable from an animal, vegetable, or mineral source and convertible into nonwoven fabrics such as felt or paper or, after spinning into yarns, into woven cloth. A natural fibre may be further defined as an agglomeration of cells in which the diameter is negligible in comparison with the length. Features of some popular synthetic fibers.

Source: researchgate.net

Source: researchgate.net

Synthetic fibres is prepared from chemical substances in the industry. The inherent characteristics and properties of natural fibers, generally issues like poor adhesion, moisture absorption, poor wet ability, etc., cause lower bonding with the polymer matrix. The automotive and aerospace sectors represent the best opportunity for natural fibers due to their favorable characteristics such as lower weight, better crash absorbance and sound insulation properties. Physical properties of wool fibre: 3.4, are oriented at an angle to the normal fiber axis called the microfibrillar angle (mfa).the structure, mfa, cell dimensions,.

Source: researchgate.net

Source: researchgate.net

Therefore, modification or pretreatment of natural fibers is done prior to composite preparation. The earliest evidence of humans using fibers. Features of some popular synthetic fibers. Synthetic fibres don’t get wrinkles after washing and are extremely lightweight. Natural fibers have proved to be an excellent reinforcement in polymers.

Source: researchgate.net

Source: researchgate.net

It is not surprising that the natural fibre composite is. They can be used as a component of composite materials, where the orientation of fibers impacts the properties. A natural fibre may be further defined as an agglomeration of cells in which the diameter is negligible in comparison with the length. If a fiber cannot absorb moisture, it feels clammy, and can plaster itself to your skin. Molaba, in encyclopedia of materials:

Source: researchgate.net

Source: researchgate.net

Natural fibers can also be matted into sheets to make paper or felt. Molaba, in encyclopedia of materials: Cashmere obtained from cashmere goats and other goats. The inherent characteristics and properties of natural fibers, generally issues like poor adhesion, moisture absorption, poor wet ability, etc., cause lower bonding with the polymer matrix. Natural fibre, any hairlike raw material directly obtainable from an animal, vegetable, or mineral source and convertible into nonwoven fabrics such as felt or paper or, after spinning into yarns, into woven cloth.

Source: eduzoneclasses.com

Source: eduzoneclasses.com

Natural fibers may be classified into three main categories that are plant fibers, animal fibers,. Absorbent fibers have less static cling. Therefore, modification or pretreatment of natural fibers is done prior to composite preparation. Clothing made for warmth, blankets, and furnishings. Collection, sorting/scouring, dehairing, spinning, weaving/knitting main uses:

Source: oasistextiles.com

Source: oasistextiles.com

Nylon has a lower specific gravity than other fibres. Natural fibers are produced by plants, animals, and geological processes. The inherent characteristics and properties of natural fibers, generally issues like poor adhesion, moisture absorption, poor wet ability, etc., cause lower bonding with the polymer matrix. Collection, sorting/scouring, dehairing, spinning, weaving/knitting main uses: Physical properties of wool fibre:

Source: novapublishers.com

Source: novapublishers.com

If a fiber cannot absorb moisture, it feels clammy, and can plaster itself to your skin. The inherent characteristics and properties of natural fibers, generally issues like poor adhesion, moisture absorption, poor wet ability, etc., cause lower bonding with the polymer matrix. Molaba, in encyclopedia of materials: They are easy to maintain and wash and are resistant to attack by moths. Nylon has a lower specific gravity than other fibres.

![Chemical Properties of Natural Fiber [65 73] Download Table Chemical Properties of Natural Fiber [65 73] Download Table](https://www.researchgate.net/publication/325212353/figure/download/tbl1/AS:667702007971848@1536203972540/Chemical-Properties-of-Natural-Fiber-65-73.png) Source: researchgate.net

Source: researchgate.net

The natural fibers have been abundantly available in the world. A natural fibre may be further defined as an agglomeration of cells in which the diameter is negligible in comparison with the length. Fiber obtained from natural sources like plants and animals, for example, cotton, silk, wool etc. Most natural fibres have considerable differences in mechanical properties and moisture absorption and have poor thermal characteristics, creating problems in the production of natural fibre composites. The natural fibers have been abundantly available in the world.

Source: researchgate.net

Source: researchgate.net

If a fiber cannot absorb moisture, it feels clammy, and can plaster itself to your skin. Although nature abounds in fibrous. Because the inherent characteristics of fibres directly relate to the finished fabric�s performance and the maintenance required, understanding fibres and yarns will in turn help you to understand how to incorporate fabrics into your interior scheme. The earliest evidence of humans using fibers. Cashmere obtained from cashmere goats and other goats.

Source: rftp.com

Source: rftp.com

Cashmere obtained from cashmere goats and other goats. Therefore, modification or pretreatment of natural fibers is done prior to composite preparation. Clothing made for warmth, blankets, and furnishings. They can be used as a component of composite materials, where the orientation of fibers impacts the properties. Visit byju’s to learn more about, examples, types, advantage, videos and faqs of synthetic and natural fibres.

Source: slideserve.com

Source: slideserve.com

Examples of bast fibres include jute fibres, flax fibres, vine fibres, industrial hemp fibres, kenaf fibres, rattan fibres, and ramie fibres. While designing composite parts, the. Fiber obtained from natural sources like plants and animals, for example, cotton, silk, wool etc. It can be noted that these fibres are widely used in fabric and packaging due to their durable. Examples of bast fibres include jute fibres, flax fibres, vine fibres, industrial hemp fibres, kenaf fibres, rattan fibres, and ramie fibres.

Source: slideshare.net

Source: slideshare.net

Absorbent fibers have less static cling. Most natural fibres have considerable differences in mechanical properties and moisture absorption and have poor thermal characteristics, creating problems in the production of natural fibre composites. Cashmere obtained from cashmere goats and other goats. You can find natural and synthetic fibers among the world�s most used fibers for textiles. Natural fibers can also be matted into sheets to make paper or felt.

![characteristics of synthetic fibers by edutree [HD] YouTube characteristics of synthetic fibers by edutree [HD] YouTube](https://i.ytimg.com/vi/xTr7QkpXtE4/maxresdefault.jpg) Source: youtube.com

Source: youtube.com

The earliest evidence of humans using fibers. Natural fibers or natural fibres (see spelling differences) are fibers that are produced by geological processes, or from the bodies of plants or animals. Natural fibers can also be matted into sheets to make paper or felt. Availability of natural fibres (like coir, abaca, banana, jute, sisal, cotton) are huge in india. Most natural fibres have considerable differences in mechanical properties and moisture absorption and have poor thermal characteristics, creating problems in the production of natural fibre composites.

If you find this site beneficial, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title characteristics of natural fibres by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.