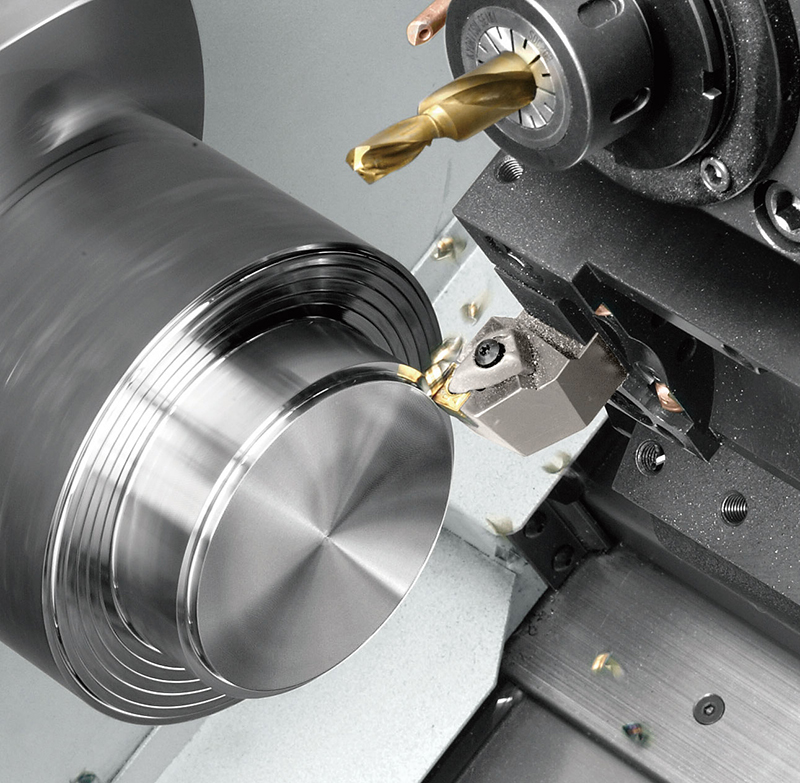

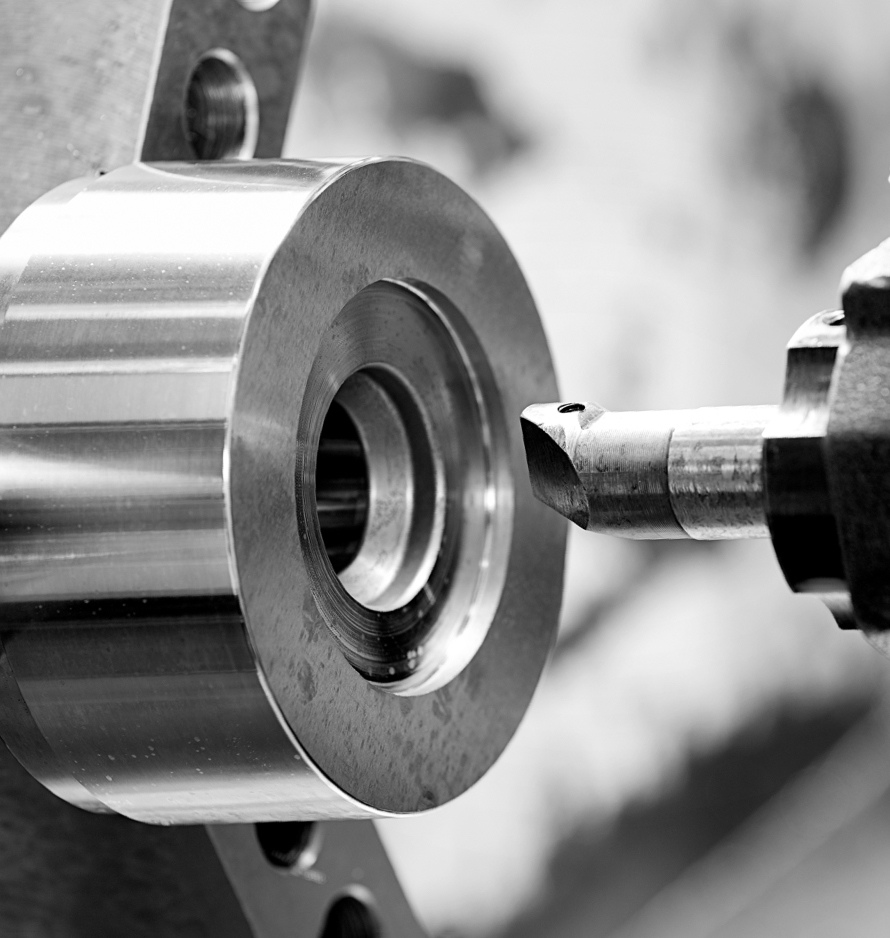

Machining o1 tool steel

Machining O1 Tool Steel. This group of steels contains o2, o6, o7 and o1 tool steels. 01 will not readily work harden like an air hardening steel will, just keep your tools sharp and all is good. Tool and machining steel nan. O1 tool steel is an oil hardening, cold work general purpose steel with easy machining properties and low hardening temperatures compared to other grades.

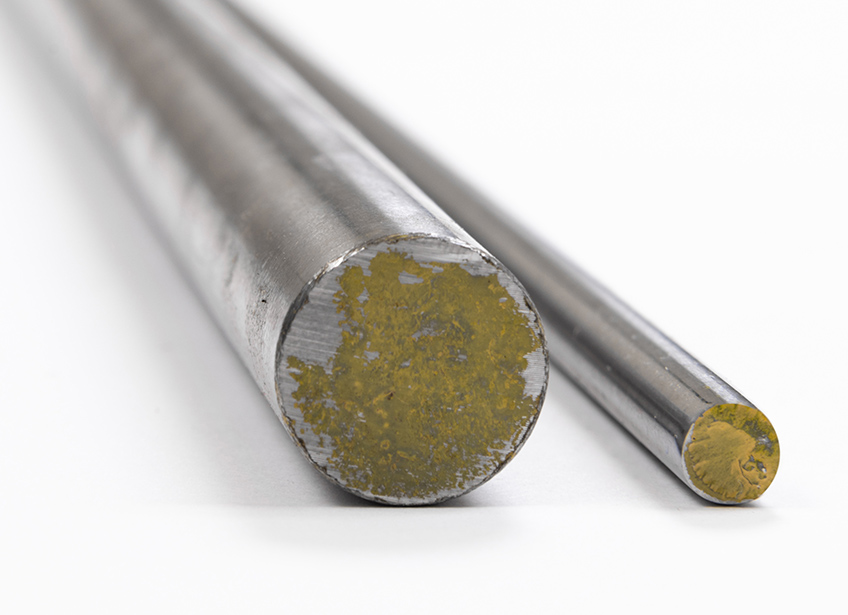

O1 Oil Hardening Tool Steel Rod 1 1/4" Dia. (+.051") x 3 Foot Length eBay From ebay.com

O1 Oil Hardening Tool Steel Rod 1 1/4" Dia. (+.051") x 3 Foot Length eBay From ebay.com

View suppliers ( 49) equivalent materials to aisi o1. O1 oil hardening tool steel annealing heat slowly and uniformly to 1140°f; Cooling is done in still air. Distributors will offer small quantity buys while mills will generally only sell large quantities, with delivery times anywhere from 10 to 50 weeks depending on size and form required. Is a good general use multi purpose tool steel, and yes on 65 rc. O1 isn�t available in bar form, only sheets cut to width+ then ground to size.

Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes.

I make special cutters from 01 or w1 frequently. See the equivalents for din, afnor, bs, une, sae, jis, en, iso, gost, gb/t and uns. View suppliers ( 49) equivalent materials to aisi o1. The composition of o1 tool steel is different from many other types of steel out there but gives it a unique edge. Is a good general use multi purpose tool steel, and yes on 65 rc. When i first started out we�d machine it with hss, so no problems at all using carbide tooling.

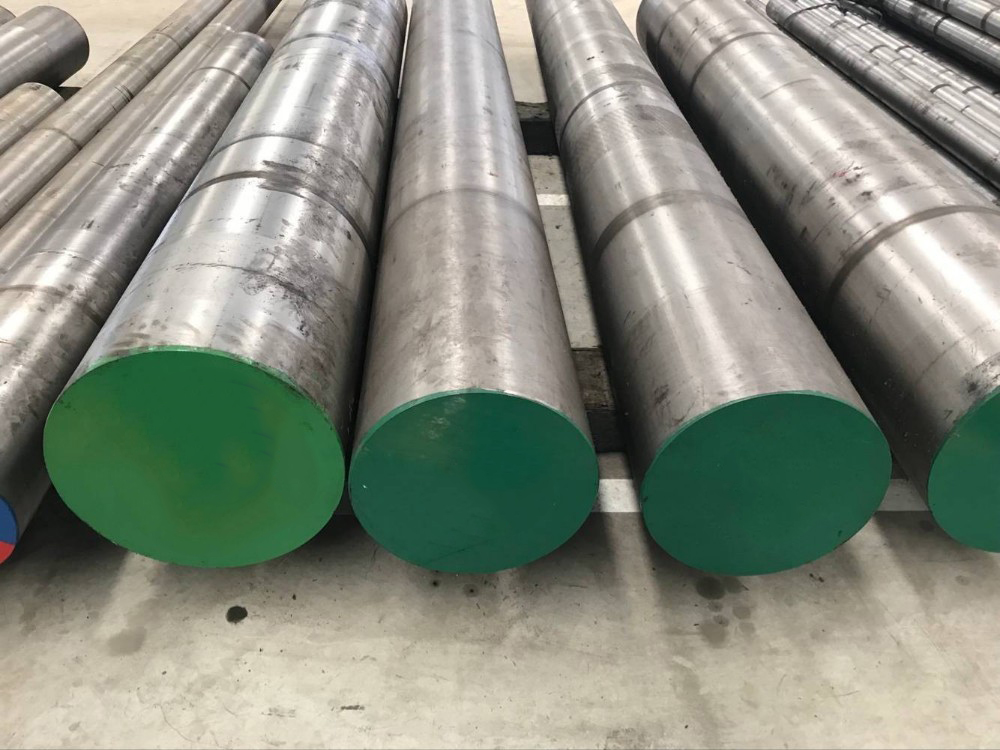

Source: otaisteel.com

Source: otaisteel.com

Your email * password *. O1 tool steel is a high carbon steel alloy that provides excellent cutting and other machining applications. Tool and machining steel nan. Upload your parts for free dfm analysis. Steel o1 belongs to the o series of tool steels.

Source: kapitalsteel.com

Source: kapitalsteel.com

Below is our stock sizes and availability for o1 tool steel. Steel is by far the most popular material in machine shops. Steel o1 has a machinability rating of 42%. We welcome all enquiries for o1 steel materials and if you would like some friendly advice, call us on 0114 233 5291. O1 is also commonly used for industrial machine knives, blades, cams and more.

Source: goodmetals.com

Source: goodmetals.com

Upload your parts for free dfm analysis. The composition of o1 tool steel is different from many other types of steel out there but gives it a unique edge. What is o1 tool steel? Your email * password *. Cnc machining metal tool steel tool steel o1.

Source: ebay.com

Source: ebay.com

Tool steels o1 is stocked by 72 north american distributors and produced by 13 large mills. You can learn more about the influence of carbon in our article about carbon steel. Distributors will offer small quantity buys while mills will generally only sell large quantities, with delivery times anywhere from 10 to 50 weeks depending on size and form required. O1 tool steel is an oil hardening, cold work general purpose steel with easy machining properties and low hardening temperatures compared to other grades. View suppliers ( 49) equivalent materials to aisi o1.

Source: ebay.com

Source: ebay.com

Steel o1 belongs to the o series of tool steels. The composition of o1 tool steel is different from many other types of steel out there but gives it a unique edge. The lathe needs to run as slow as possible for carbon steel cutting tools. Due to its wear resistance, its main applications include gauges, cutting tools, woodworking tools and knives. O1 is also commonly used for industrial machine knives, blades, cams and more.

Source: ebay.com

Source: ebay.com

O1 is also commonly used for industrial machine knives, blades, cams and more. Download datasheet email this page. View suppliers ( 49) equivalent materials to aisi o1. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. O1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production.

Source: esteelsuppliers.com

Source: esteelsuppliers.com

Your email * password *. O1 is also commonly used for industrial machine knives, blades, cams and more. Stock is delivered on our own fleet of vehicles locally and nationally quickly and efficiently on the day we say we will. O1 tool steel is a high carbon steel alloy that provides excellent cutting and other machining applications. Cooling is done in still air.

Source: ebay.com

Source: ebay.com

O1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production. O1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production. O1 isn�t available in bar form, only sheets cut to width+ then ground to size. The composition of o1 tool steel offers high carbon content, which increases its hardness and wear resistance while. Press tools, broaches, clipping, marking punches, gauges, jigs, deep drawing dies, slitting cutters, taps & screwing tools.

Source: ebay.com

Source: ebay.com

Soak thoroughly and then allow to cool slowly in the furnace to below 1000ºf. Steel o1 belongs to the o series of tool steels. There are 16 equivalent materials for aisi o1 tool and machining steel. Ready to test your design? The lathe needs to run as slow as possible for carbon steel cutting tools.

Source: alibaba.com

Source: alibaba.com

We also provide a free issue cutting service, press braking, fabrication and forging. I squared and faced some stainless flat and it was horrible, and everything i can find says tool steel is way worse. O1 is also commonly used for industrial machine knives, blades, cams and more. This material is stocked primarily in bar products by. You can learn more about the influence of carbon in our article about carbon steel.

Source: zeicin.com

Source: zeicin.com

O1 oil hardening tool steel annealing heat slowly and uniformly to 1140°f; Download datasheet email this page. Upload your parts for free dfm analysis. Tool steels o1 is stocked by 72 north american distributors and produced by 13 large mills. View suppliers ( 49) equivalent materials to aisi o1.

Source: ebay.com

Source: ebay.com

O1 tool steel is a high carbon steel alloy that provides excellent cutting and other machining applications. Distributors will offer small quantity buys while mills will generally only sell large quantities, with delivery times anywhere from 10 to 50 weeks depending on size and form required. We welcome all enquiries for o1 steel materials and if you would like some friendly advice, call us on 0114 233 5291. O1 tool steel is an oil hardening, cold work general purpose steel with easy machining properties and low hardening temperatures compared to other grades. Stock is delivered on our own fleet of vehicles locally and nationally quickly and efficiently on the day we say we will.

Source: youtube.com

Source: youtube.com

Is a good general use multi purpose tool steel, and yes on 65 rc. O1 isn�t available in bar form, only sheets cut to width+ then ground to size. 01 will not readily work harden like an air hardening steel will, just keep your tools sharp and all is good. O1 provides good wear resistance and toughness sufficient for standard tool and die applications making it a suitable choice for tooling with good tool life and econimcal production. We also provide a free issue cutting service, press braking, fabrication and forging.

Source: quadranttool.com

Source: quadranttool.com

It would be a standard screwless vise, milled to.005, treated and ground. You can learn more about the influence of carbon in our article about carbon steel. The composition of o1 tool steel offers high carbon content, which increases its hardness and wear resistance while. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Distributors will offer small quantity buys while mills will generally only sell large quantities, with delivery times anywhere from 10 to 50 weeks depending on size and form required.

Source: hubs.com

Source: hubs.com

O1 tool steel normalizing treatment temperature: Cnc machining metal tool steel tool steel o1. Below is our stock sizes and availability for o1 tool steel. When i first started out we�d machine it with hss, so no problems at all using carbide tooling. There are 16 equivalent materials for aisi o1 tool and machining steel.

Source: kapitalsteel.com

Source: kapitalsteel.com

I make special cutters from 01 or w1 frequently. Steel o1 belongs to the o series of tool steels. What is o1 tool steel? I want to make a vise, and the head of shop at my university has very strongly recommended a2, d2 or o1 to do it. O1 tool steel must be hardened by quenching in oil.

Source: ebay.com

Source: ebay.com

A strong alloy steel like sae 4340 has a tensile strength of 10,800 psi (745 mpa), while a common tool steel alloy such as o1 has 26,100 psi (1,800 mpa). There are 16 equivalent materials for aisi o1 tool and machining steel. I�ve nearly gotten 67 at times. Stock is delivered on our own fleet of vehicles locally and nationally quickly and efficiently on the day we say we will. Steel o1 has a machinability rating of 42%.

Source: ebay.com

Source: ebay.com

Is a good general use multi purpose tool steel, and yes on 65 rc. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. 01 will not readily work harden like an air hardening steel will, just keep your tools sharp and all is good. Upload your parts for free dfm analysis. How the hell do i do that.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title machining o1 tool steel by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.