How is a battery leakage test conducted

How Is A Battery Leakage Test Conducted. How is the battery leakage test conducted? Here are two of the key challenges you are likely to encounter with battery pack leak testing and strategies to overcome them. If any current is registered on the voltmeter, the top of the battery needs to be cleaned. Leakage current measurement in medical devices.

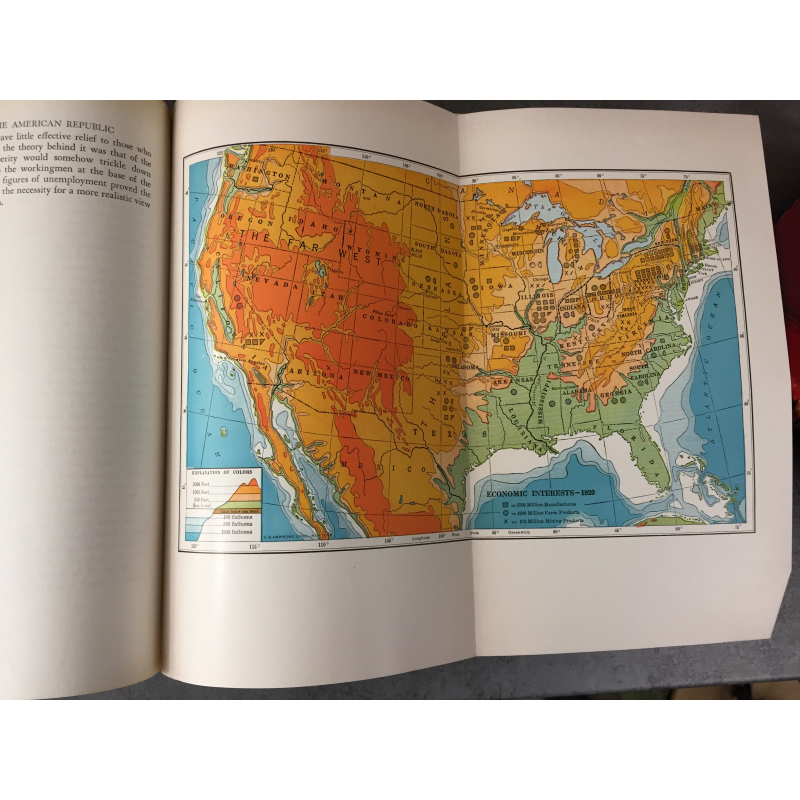

Pm6310 Sms Battery Powered Lpg Gas Leakage Detector Gas Cylinder From alibaba.com

Pm6310 Sms Battery Powered Lpg Gas Leakage Detector Gas Cylinder From alibaba.com

One other reason is external leakage currents, which can be caused by a number of factors including battery terminal contamination or oxidation, car wiring insulation failure, or even incorrect connection of after market equipment like car radios. Leakage current testing is used to verify that the product does not leak excessive current when contacted by the user. Deep cycle batteries are designed to gothrough many charge and discharge cycles.b. Thoroughly clean the battery case and posts with the solution, using a soft brush, and wipe the case with paper towels. Depending on the customer�s specifications, the production phase of the part under test, cycle time, etc. Be notified when an answer is posted.

A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test.

Prepare a solution of 1 tbsp. The limit for the leakage test was changed in the 5 th edition of the iet code of practice to 5ma. After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover assembled, we do the final battery pack leak test. Our experts can work with your application requirements to make equipment and test method recommendations that will offer the shortest. After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover. There is a problem with the exhaust valve, and the sealing is not good.

Source: gas-detectors.gasdetectors.us

Source: gas-detectors.gasdetectors.us

Leakage current measurement in medical devices. Our experts can work with your application requirements to make equipment and test method recommendations that will offer the shortest. There is a defect in the glue drop of the terminals. Caused by the production process, or caused by too long welding time. Of baking soda in 8 ounces of warm water in a small bowl.

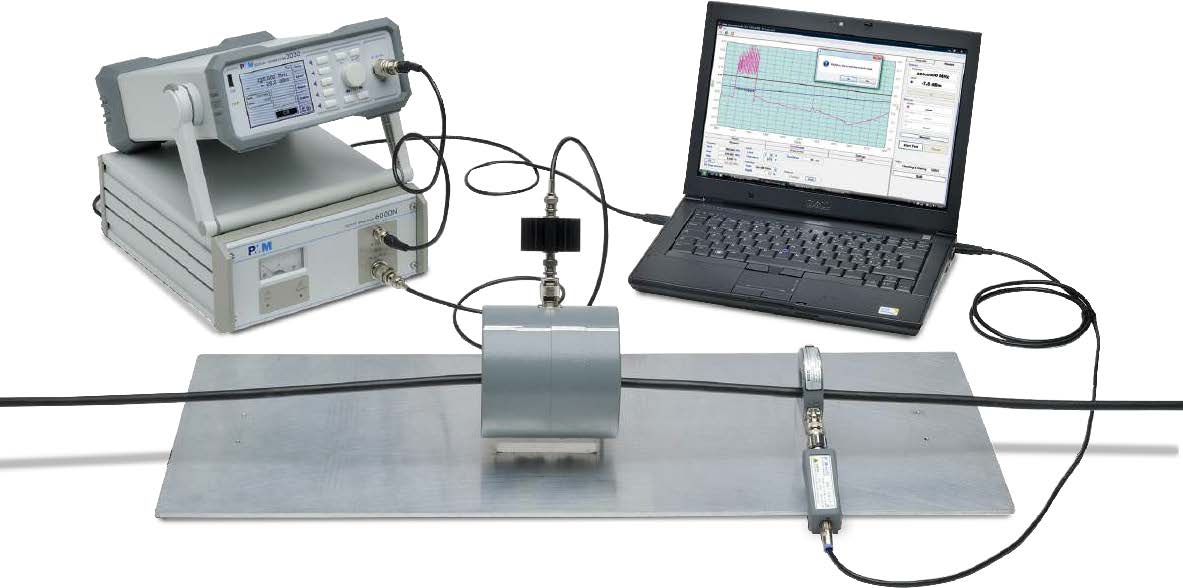

Source: electrotestsafety.com.au

Source: electrotestsafety.com.au

Rapid detection of leaks in the production of battery cells is absolutely essential to achieving necessary service life and safety requirements. Leakage current testing is used to verify that the product does not leak excessive current when contacted by the user. Deep cycle batteries are designed to gothrough many charge and discharge cycles.b. Prepare a solution of 1 tbsp. There are many reasons a car battery is drained, including normal wear and tear of the battery, alternator failure, and starter malfunction.

Source: alibaba.com

Source: alibaba.com

Solutions for chapter 17 problem 3rq: The limit for the leakage test was changed in the 5 th edition of the iet code of practice to 5ma. We test also the cover and bottom. Ioniq wind leak testing is the best technology to use when leak testing battery pouches and motor coil coverings. A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test.

Source: portable.gas-cap.org

Source: portable.gas-cap.org

We supply an intermediate system to test the parts before the cover is assembled with the frame and the final leak test station to test the finished battery tray with the bottom already assembled. Of baking soda in 8 ounces of warm water in a small bowl. Posted january 27, 2021 by tom lombardo & filed under features, fleets and infrastructure features, tech features. A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test. Prepare a solution of 1 tbsp.

Source: indiamart.com

Source: indiamart.com

Battery pack trays and lids are made out of several types of materials, which can affect leak testing applications. We also leak test the cooling circuits before and after assembly. A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test. Excessive liquid level during acid filling will cause the acid leakage from the terminals. Ioniq wind leak testing is the best technology to use when leak testing battery pouches and motor coil coverings.

Source: jrautofix.com.au

The objective of the leakage current test is to verify that the electrical insulation used to protect the user from a risk of shock is suitable for the application. After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover assembled, we do the final battery pack leak test. How is a battery leakage test conducted?. We also leak test the cooling circuits before and after assembly. The lifetime of a battery strongly depends on the tightness of the cell housing, because of the harmful effects caused by the interaction between the electrolyte and water vapor.

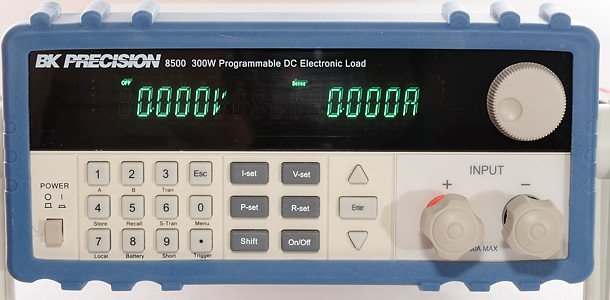

Source: hvhipot.com

Source: hvhipot.com

Here are two of the key challenges you are likely to encounter with battery pack leak testing and strategies to overcome them. Get solutions get solutions get solutions done loading looking for the textbook? There is a problem with the exhaust valve, and the sealing is not good. After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover assembled, we do the final battery pack leak test. There are many reasons a car battery is drained, including normal wear and tear of the battery, alternator failure, and starter malfunction.

Source: indiamart.com

Source: indiamart.com

Posted january 27, 2021 by tom lombardo & filed under features, fleets and infrastructure features, tech features. Depending on the customer�s specifications, the production phase of the part under test, cycle time, etc. About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. Battery pack trays and lids are made out of several types of materials, which can affect leak testing applications. Leak testing plays a critical role in the assembly of battery cells, modules and packs.

Source: alibaba.com

Source: alibaba.com

After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover. One other reason is external leakage currents, which can be caused by a number of factors including battery terminal contamination or oxidation, car wiring insulation failure, or even incorrect connection of after market equipment like car radios. Excessive liquid level during acid filling will cause the acid leakage from the terminals. Depending on the customer�s specifications, the production phase of the part under test, cycle time, etc. Posted january 27, 2021 by tom lombardo & filed under features, fleets and infrastructure features, tech features.

.jpg “FEASIBILITY STUDY TO TEST CONTROLIT GS MATERIAL Buckleys Case Studies”) Source: buckleysinternational.com

We supply an intermediate system to test the parts before the cover is assembled with the frame and the final leak test station to test the finished battery tray with the bottom already assembled. The limit for the leakage test was changed in the 5 th edition of the iet code of practice to 5ma. Deep cycle batteries are designed to gothrough many charge and discharge cycles.b. The most common reason why equipment often appears to fail a leakage test is that an incorrect limit is used. Ioniq wind leak testing is the best technology to use when leak testing battery pouches and motor coil coverings.

Source: mdltechnologies.co.uk

Source: mdltechnologies.co.uk

Get solutions get solutions get solutions done loading looking for the textbook? In a gel cell battery, gassing is minimized andvents are not needed. Leakage current testing is used to verify that the product does not leak excessive current when contacted by the user. Rapid detection of leaks in the production of battery cells is absolutely essential to achieving necessary service life and safety requirements. How is a battery leakage test conducted?.

Source: indiamart.com

Source: indiamart.com

The lifetime of a battery strongly depends on the tightness of the cell housing, because of the harmful effects caused by the interaction between the electrolyte and water vapor. Our experts can work with your application requirements to make equipment and test method recommendations that will offer the shortest. There are many reasons a car battery is drained, including normal wear and tear of the battery, alternator failure, and starter malfunction. In a gel cell battery, gassing is minimized andvents are not needed. Thoroughly clean the battery case and posts with the solution, using a soft brush, and wipe the case with paper towels.

Source: alibaba.com

Source: alibaba.com

Of baking soda in 8 ounces of warm water in a small bowl. Rapid detection of leaks in the production of battery cells is absolutely essential to achieving necessary service life and safety requirements. How is a battery leakage test conducted?. Excessive liquid level during acid filling will cause the acid leakage from the terminals. In a gel cell battery, gassing is minimized andvents are not needed.

Source: forcetools-kepmar.eu

Source: forcetools-kepmar.eu

Defective cells can shorten battery life, decrease range, and lead to safety issues. We test also the cover and bottom. Ioniq wind leak testing is the best technology to use when leak testing battery pouches and motor coil coverings. The most common reason why equipment often appears to fail a leakage test is that an incorrect limit is used. After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover assembled, we do the final battery pack leak test.

Source: indiamart.com

Source: indiamart.com

How is a battery leakage test conducted?. After the battery pack is completed with all the batteries cell inserted, electronic units connected and the cover. Get solutions get solutions get solutions done loading looking for the textbook? A leakage test allows the battery housing and its components to be checked for appropriate leakage requirements at an early stage. There is a defect in the glue drop of the terminals.

Source: alibaba.com

Source: alibaba.com

To perform a battery leakage test, set a voltmeter on a low setting. Ateq’s ioniq or b28 electrical leak testers use safe low ionization voltages to ionize oxygen molecules in the air around the test part and display an insulation percentage to see if the part is within specification. There is a defect in the glue drop of the terminals. In a gel cell battery, gassing is minimized andvents are not needed. Get solutions get solutions get solutions done loading looking for the textbook?

Source: lygte-info.dk

Source: lygte-info.dk

Battery pack trays and lids are made out of several types of materials, which can affect leak testing applications. A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test. Excessive liquid level during acid filling will cause the acid leakage from the terminals. A leakage test allows the battery housing and its components to be checked for appropriate leakage requirements at an early stage. Defective cells can shorten battery life, decrease range, and lead to safety issues.

Source: axleaddict.com

Source: axleaddict.com

Posted january 27, 2021 by tom lombardo & filed under features, fleets and infrastructure features, tech features. We also leak test the cooling circuits before and after assembly. If any current is registered on the voltmeter, the top of the battery needs to be cleaned. One other reason is external leakage currents, which can be caused by a number of factors including battery terminal contamination or oxidation, car wiring insulation failure, or even incorrect connection of after market equipment like car radios. Defective cells can shorten battery life, decrease range, and lead to safety issues.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how is a battery leakage test conducted by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.